New Innovation

The Atsumitec Group is committed to achieving an eco-friendly environment. At Ada Technologies, we embrace this corporate effort to recycle materials, conserve our resources and energy, from original design, introduction, growth, maturity and decline.

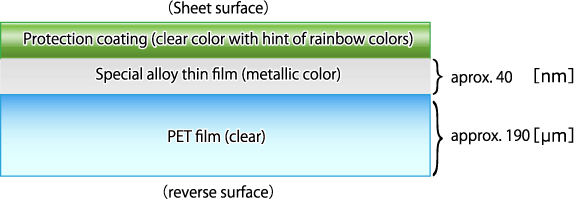

Film Diagram

Film Highlights

As shown in the image above, there is a thin membrane made up of a special alloy, on top of a transparent PET (polyethylene terephthalate) film. It reacts only to hydrogen gas. When hydrogen gas flows in, this thin alloy layer seizes the hydrogen and becomes transparent, indicating the presence of hydrogen. A protective topcoat is applied so it is still possible to directly touch the surface of the film, without minimizing the functionality.

![]()

Hydrogen Detectable Sheet

In keeping with the company philosophy of creating new value for our customers, Atsumitec Co. Ltd. of Japan has developed an advanced technology: Hydrogen Detectable Sheet.

Although not yet available in the United States, this revolutionary product was developed at our Atsumitec Headquarters in Japan by a dedicated team focused on advanced directives with a goal of achieving an eco-friendly, hydrogen environment. Collaborating globally with members of academia, government and industry leaders, the “Fukuoka Hydrogen Energy Plan Conference” was established. The result of these advanced technology-initiatives was the implementation of the Visible Hydrogen Sheet.

When this innovative metallic color material comes in contact with hydrogen, the sheet changes to clear and colorless within a mere 3 seconds. When the hydrogen element is removed, the distinctive sheet returns back to its original metallic color. Thus, this leading-edge, advanced technology material can be used repeatedly.

Product Highlights:

- Contact with hydrogen gas changes the material from a metallic color to colorless and transparent.

- Once the hydrogen gas is removed, the material properties allow the advanced material to change back to its original color and the value-added properties of re-use.

Applications:

- This material can be used to detect the presence of hydrogen gas or to check for hydrogen outflow or leakage in critical connection areas.

- Its hydrogen gas detection properties can be utilized without the aid of external power.

- Product flexibility allows the material sheet to be cut to shape and size, allowing the use in a variety of applications.

(*1) Depending on its usage environment, it is possible to see low concentration Hydrogen as well. – As for Hydrogen concentrations over 0.4%~100%, durability/response time will change

(*2) Response time for 60% as opposed to full response (100%)

– (60% = transparency level where visual detection is possible)

(*3) Performance reference. May change based on Hydrogen concentration (amount/partial pressure of Hydrogen)

(*4) A detectable heatproof temperature. Durability may change based on temperature/humidity

(*5) This is the limit value where the film does not separate and sheet return to original shape

(*6) Hydrogen visualization sheets pieced together using adhesive film

(*7) Environment: normal room temperature/humidity. However, this will increase/decrease based on usage environment

(*8) When re-using, we recommend heating it up to 80°C/hr using a Thermostatic/Humidity Testing Chamber, etc.

– When returning it to original condition by room temperature, leave overnight in a dry room with good air circulation

Hydrogen Detectable Sheet Specifications

| Material | Protective Film/Special Alloy Thin Film/PET Film | ||

| Reactant Gas | Hydrogen Only | ||

| Reactant Hydrogen Concentration |

100% Pure Hydrogen (*1) | ||

| Response Time [T60 (*2)] | 3 sec or less (100% H2 50ml/min 0.1 [MPa]) (*3) | ||

| Usage Environment | Room Temperature (no waterproofing) | ||

| Heatproof Temperature | 100°C (*4) | ||

| Bend | Capable of up to R30 [mm] (*5) | ||

| Size | 130 [mm] x 130 [mm] | Large Format (*6) | |

| 30 [mm] x 30 [mm] | 200 [mm] x 450 [mm] | ||

| Repeat Usage Limit | 10 Times (*7) | 30 Times (*8) | |

(419) 634-7000

(419) 634-7000